The triple filtration in the Biofilter

- Filtration 1: Pre-filtration: Spunbond (made with thermally welded filaments, 100% polypropylene) mixed with fibers. Sediment filter which retains particles of iron, sand, mud, neutralizes the development of germs, bacteria etc … and protects the activated carbon block

- Filtration 2: the Carbon Fiber Block (patent no. 2282494) is composed of activated carbon in sintered granules (porosity 20 µm) mixed with fibers. Activated carbon is obtained after calcination of coconut shells (increases the number of micropores) by injection of pressurized hot water vapor (activation of the carbon by different temperature levels of 900°C-1,000°C for several hours; activated carbon is regenerated by oxidation Chemical filtration of chlorine, nitrates, nitrites, organic pesticides and herbicides, tastes and odors

- the activated carbon physically retains pollutants in its structure up to diameters of 5 µm (physical filtration of heavy metals: lead, aluminum, bacteria, arsenic and parasites) ; (patent n° 2429067)

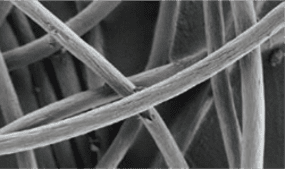

- Filtration 3: Aqualen fiber (patents n° 20704036 & US n° 6514413) ; fiber with a fiber diameter of 10 µm, mixed with activated carbon. This fiber resembles the roots of a tree which bind the granules of activated carbon into a dense structure. Its function is threefold, it:

- allows you to have a very large adsorption surface, that is to say a good distribution of water over the entire surface of the activated carbon (this avoids preferential water channels)

- incorporates in its structure ionized silver which is bactericidal (neutralizes microorganisms, antibiotics, drugs etc…), the silver is therefore not mixed with the activated carbon but retained in the microfiber ; (patent n° 2172720)

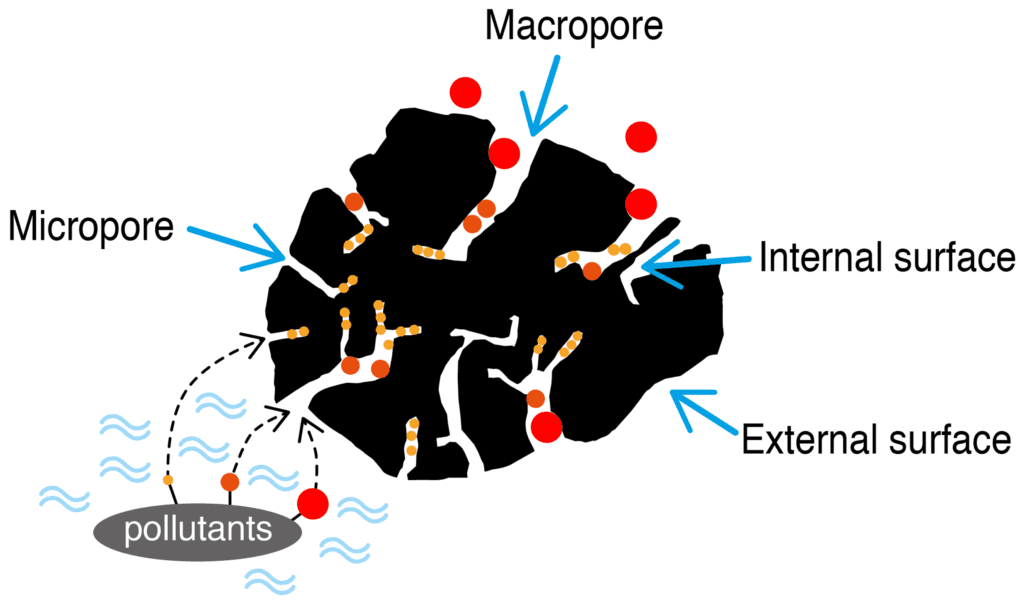

Activated carbon filtration principle = adsorption surface

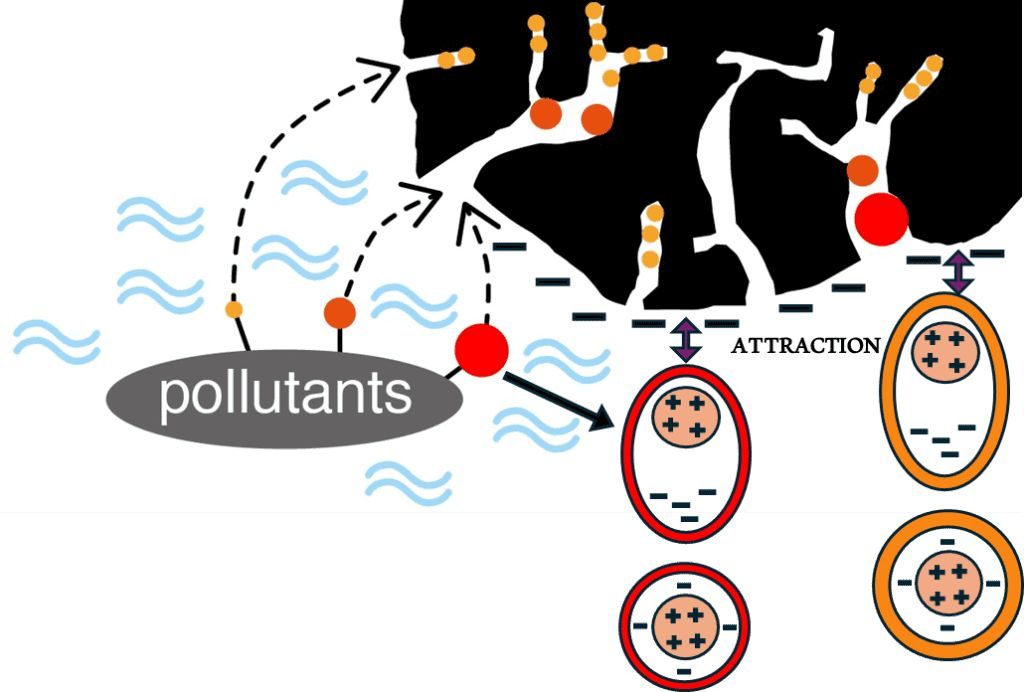

Activated carbon: Principle of physical filtration (physisorption) of pollutants (organic pesticides, heavy metals, PFAS, drugs, hormones, etc. measured in µg/l)

- Electro-adsorption surface

The pollutants (their electropositive parts) will be “Attracted“, by potential difference, by the electronegative surface of the activated carbon (the carbon has available electrons on its surface which will attract the electropositive parts of the polluting molecules = Van Der Waals forces: intermolecular bond forces due to low intensity electrical interactions = electrostatic)

- Physical adsorption surface

Activated carbon will also “Retain” non-soluble pollutants (hydrophobic), i.e. non-polarized or weakly polarized pollutants, in its porous structure (external and internal). This is made up of micropores (millions of empty microscopic alveoli) whose size is between <2 nm and 50 nm in diameter. The more micropores there are, the more empty spaces there are that can fix pollutants and the greater the adsorption surface.

Size of the adsorption surface in the Biofilter

The 3 kgs of activated carbon from coconuts in the Biofilter, mixed with the hollow fiber, provide an adsorption surface equivalent to 900 football fields of 1 hectare!!! (3,000 m2/g of activated carbon x 3 Kg), i.e. a surface area 33 times larger than that of conventional filters!